Copper is an essential metal used globally in construction, electronics, transportation, and infrastructure. The demand for copper continues to grow as technology advances and green energy initiatives expand.

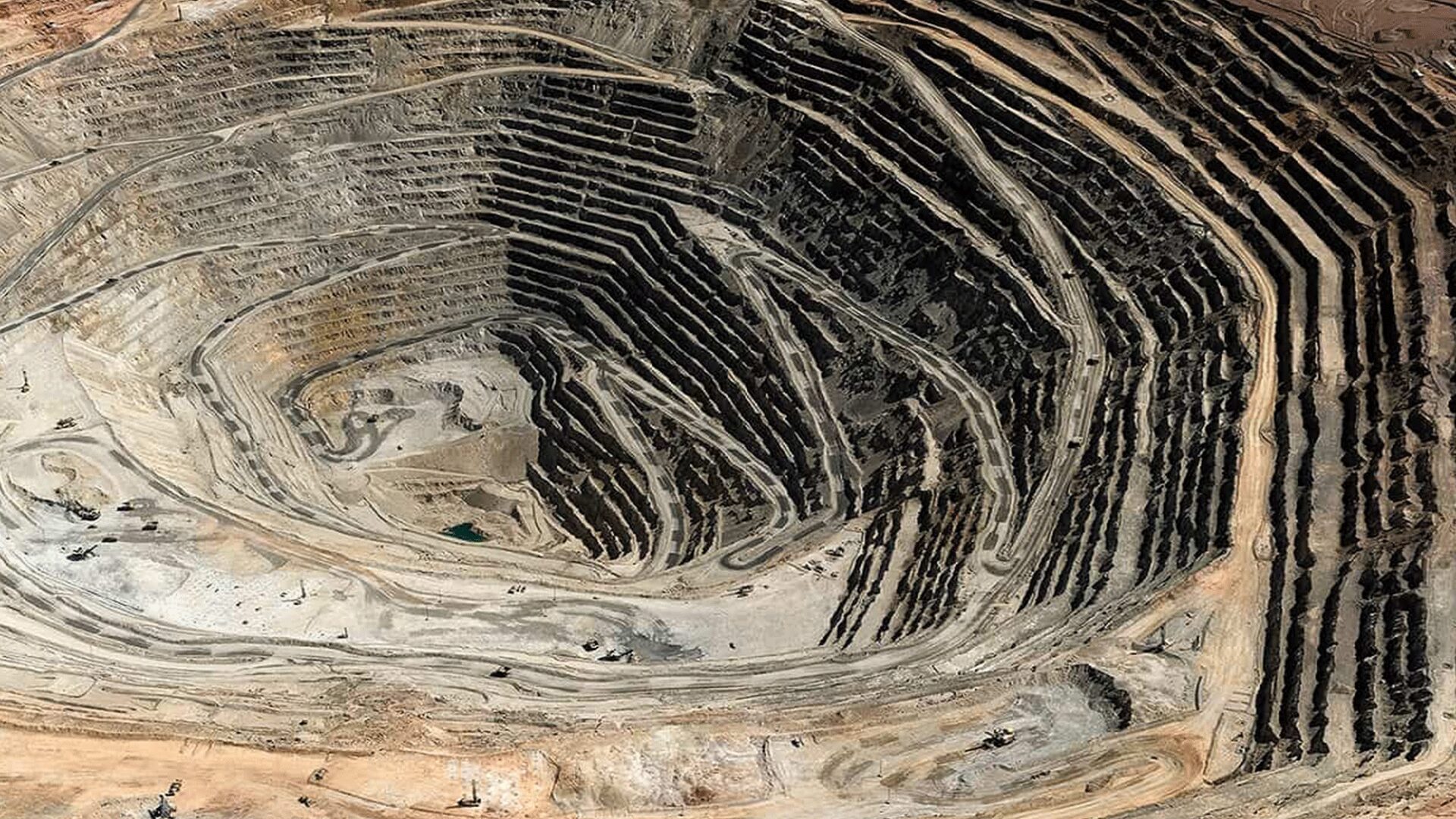

This comprehensive guide explores the top copper mines around the world, their mining methods, production output, environmental considerations, and economic impact. Many of the world’s largest copper mines have achieved global significance due to their immense scale and advanced technology. Impressive infrastructure has been built at major copper mining sites, including extensive shafts, smelting works, and processing facilities.

From the vast open-pit mines of Chile and the United States some of which are located west of Phoenix, Arizona to underground operations in the Democratic Republic of Congo, we cover the key sites shaping the copper mining industry today.

Understanding Copper Ore and Deposits

Copper ore is typically found in sulfide minerals, which require sophisticated processing to extract the metal.

Copper ores are often mined alongside other valuable metals, including molybdenum, silver, and gold. Iron is also a common mineral found with copper, further illustrating the mineral diversity of these deposits.

Copper is mined from both concentrated and lower grade ores, depending on the geological setting. The source of copper and associated minerals can often be traced to specific geological formations that control ore distribution.

Background levels of naturally occurring substances, including radionuclides, are present in copper ore deposits and serve as reference points when assessing environmental impacts. The extraction process yields copper cathode, a refined product used in manufacturing.

Largest Copper Mines Around the World

1. Escondida Mine, Chile

The Escondida Mine in Antofagasta, Chile, is the world’s largest copper-producing mine. Owned by BHP Group, it produces over 880,000 tonnes of copper annually through extensive surface mining operations, resulting in the production of concentrated copper products.

The mine also produces copper cathodes as part of its processing operations. Mining and processing methods are combined at Escondida, as the mine employs heap leaching and advanced processing technologies to maximize copper concentrate output.

2. Morenci Mine, Arizona, United States

Morenci is North America’s largest copper mine and one of the largest globally, located approximately 200 miles east of Phoenix in the state of Arizona. T

he Morenci mine site, owned by Freeport McMoran Inc, has been in operation since before World War II, with significant developments and ownership changes occurring during the first half of the 20th century. Extensive infrastructure, including shafts, smelting works, and processing facilities, has been built at Morenci to support its operations.

The mine produces over 900 million pounds of copper annually, with copper cathode and molybdenum concentrate produced using heap leaching pads and solvent extraction methods. Cathodes from Morenci are also processed at the Miami rod mill, along with cathodes from other North American copper mines.

Mining and processing methods are combined at Morenci to maximize efficiency and copper recovery. The mine’s continuous expansion projects and advanced smelter facilities contribute significantly to the U.S. copper supply.

3. Grasberg Mine, Indonesia

Operated by Freeport McMoran, the Grasberg mine site is a major underground and surface mine with rich copper and gold deposits. The Grasberg site produced approximately 600,000 tonnes of copper annually in recent years.

At Grasberg, underground block caving and surface mining methods are combined to maximize extraction efficiency. The mine also has significant potential for future development and resource expansion, with ongoing studies assessing the feasibility of tapping additional reserves.

4. Antamina Mine, Peru

Located in the Ancash region, the Antamina mine site produces copper, zinc, and molybdenum concentrates. The mine has produced over 400,000 tonnes of copper annually in recent years. At Antamina, mining and processing methods are combined to efficiently extract and process multiple metals. It is a large-scale surface mine that has played a vital role in Peru’s mining industry. The site also has significant potential for future development and resource expansion.

5. Collahuasi Mine, Chile

Located at a high-altitude site in northern Chile, the Collahuasi Mine is one of the world’s largest copper operations. In 2023, the mine produced over 600,000 tonnes of copper. Mining and flotation processing methods are combined at Collahuasi to maximize copper recovery. The site also has significant potential for future expansion, with ongoing exploration and feasibility studies.

6. Cerro Verde Mine, Peru

The Cerro Verde Mine site is situated near Arequipa, Peru. In recent years, Cerro Verde has produced more than 450,000 tonnes of copper annually. The operation combines open-pit mining with a large-scale concentrator facility. There is potential for further development as new reserves are evaluated.

7. Buenavista del Cobre Mine, Mexico

This mine site in Sonora, Mexico, is one of the oldest and largest copper mines in the country. Buenavista del Cobre produced approximately 500,000 tonnes of copper in 2023. The mine uses combined open-pit mining and solvent extraction-electrowinning processes. The site’s potential for resource expansion is supported by ongoing exploration.

8. Kamoa-Kakula Project, Democratic Republic of Congo

The Kamoa-Kakula site is a major new copper project in the DRC. In its first full year of operation, the project produced over 300,000 tonnes of copper. The project combines underground mining with state-of-the-art processing technology. There is significant potential for future growth as additional phases are developed.

9. El Teniente Mine, Chile

El Teniente is a large underground mine site located south of Santiago, Chile. The mine produced around 450,000 tonnes of copper in 2023. Mining and processing operations are combined through a network of tunnels and concentrators. The site has potential for further development with ongoing modernization projects.

10. Cobre Panama Project, Panama

The Cobre Panama site is one of the largest new copper mines in the world. In 2023, it produced over 350,000 tonnes of copper. The project combines open-pit mining with a modern processing plant. There is potential for future expansion as additional deposits are explored.

Copper Mining Methods

Copper mining involves both surface (open-pit) and underground mining. Open-pit mining is the most common, especially for large, near-surface deposits. Underground mining targets deeper deposits and often involves block caving or cut-and-fill methods. In modern copper mining, mining and processing methods are often combined to maximize efficiency and resource recovery.

Copper is extracted from a variety of ores, including sulfide and oxide ores, each with distinct mineral compositions and processing requirements. The source of copper and associated minerals is typically large porphyry deposits or other mineralized zones.

Heap leaching is a widely used process that involves stacking ore on pads and applying sulfuric acid to dissolve copper. Certain waste streams from this process can contain concentrated amounts of by-products, which require careful management. The pregnant leach solution is then processed via solvent extraction and electrowinning to produce copper cathodes.

Environmental Considerations

Copper mining generates significant waste, including tailings and waste rock, which may contain naturally occurring radioactive materials (TENORM). Environmental monitoring often compares current radiological levels to background levels of radionuclides as a baseline. Certain waste streams, such as raffinate, can contain concentrated amounts of TENORM, requiring careful management.

Mines implement environmental management systems to mitigate impacts such as acid mine drainage and landscape disturbance, and these systems are often combined to address multiple environmental impacts at each site. Site-specific environmental management practices are tailored to the unique conditions and infrastructure of each mine site. The use of sulfuric acid in heap leaching requires careful handling to prevent contamination.

The state of Arizona plays a key role in environmental oversight and monitoring of mining activities, ensuring compliance with regulations and protection of natural resources.

Sustainability efforts in the industry focus on reducing water usage, recycling waste, and adopting renewable energy sources.

Economic and Social Impact

Copper mining supports thousands of jobs worldwide and contributes billions to local and national economies. The industry fosters community development programs and infrastructure improvements in mining regions. Trade of copper is a major component of the global economy, with countries like Chile and Peru being leading exporters. Copper imports also play a crucial role in balancing supply and demand, enabling countries to meet industrial needs and maintain market stability. Many companies have outlined future plans to expand production capacity and invest in new technologies, aiming to drive further economic development in the copper mining sector. There is significant potential for future economic growth as undeveloped reserves and new projects are assessed for feasibility and brought online. The state of Arizona, for example, is a key contributor to the U.S. copper mining economy, hosting major operations and supporting regulatory oversight. The economic impact of each mining site is substantial, providing jobs, supporting local businesses, and generating tax revenue for surrounding communities.

Technology and Innovation

Advancements such as automation, robotics, drones, and data analytics are transforming copper mining. These technologies are often combined to improve safety, reduce costs, and increase production efficiency. Freeport McMoran and other major companies invest heavily in these innovations to maintain competitive advantage. There are ongoing plans for further technological advancement in copper mining, focusing on both efficiency and sustainability. The potential of new technologies to transform the industry is significant, offering opportunities for long-term growth and improved resource management. Implementation of these technologies is already underway at several key mining sites, enhancing operational capabilities and site-specific performance.

Regulatory Framework and Compliance

Copper mining in the United States operates within a robust regulatory framework designed to ensure responsible extraction and processing of copper ore. The Environmental Protection Agency (EPA) and the Bureau of Land Management (BLM) are the primary agencies overseeing copper mining activities, with a focus on safeguarding both the environment and human health. Key regulations such as the Clean Water Act and the Resource Conservation and Recovery Act set standards for water quality and waste management at copper mines, ensuring that copper production does not compromise surrounding ecosystems or communities.

The EPA’s Toxic Substances Control Act (TSCA) further regulates the use and disposal of chemicals involved in copper mining and processing, adding another layer of protection. Compliance with these regulations is essential for all copper mining operations, from exploration of copper deposits to the final production of copper cathode. The United States Geological Survey (USGS) plays a vital role by providing up-to-date data on copper deposits, copper ore reserves, and mining production, supporting both regulatory agencies and mining companies in making informed decisions. This comprehensive approach helps maintain the balance between economic development and environmental stewardship in the copper mining sector.

Market Analysis and Trends

The global copper market is experiencing dynamic growth, fueled by rising demand across construction, electronics, and transportation industries. In the United States, copper mining remains a cornerstone of the economy, with major copper mines located in Arizona, New Mexico, and Montana. These regions are home to significant copper ore reserves and are operated by industry leaders such as Freeport McMoran Inc and Rio Tinto. The increasing adoption of renewable energy technologies and electric vehicles is driving up the need for copper production, as copper is essential for wiring, batteries, and infrastructure.

Market trends indicate a shift toward more sustainable and efficient copper mining processes. Companies are investing in advanced technologies like heap leaching and solvent extraction to maximize recovery from copper ore and copper concentrates, while minimizing environmental impact. The production of high-purity copper cathode is on the rise, supporting the manufacturing of electronics and construction materials worldwide. Countries such as Chile, Peru, and the Democratic Republic of Congo continue to lead in global copper output, with ongoing investments in new mines and expansion projects. As the market evolves, the focus on responsible mining practices and innovative extraction processes ensures that copper mining remains both economically viable and environmentally conscious.

Mine Tours and Education

Several historic and active copper mines offer tours to educate the public about mining history and processes. Many of these tours take visitors directly to the mine site, where they can see firsthand the impressive infrastructure built over the years, including shafts and smelting works. Notable examples include the Morenci mine in Arizona, located near Phoenix, and the Keweenaw Copper Mine in Michigan, which showcase mining heritage and modern operations. These sites also highlight the region’s history of iron mining alongside copper, emphasizing the area’s diverse mineral resources and their economic impact.

Frequently Asked Questions (FAQ)

Q1: What are the main types of copper deposits?

A1: The primary types are ores containing sulfide minerals and oxide deposits. Sulfide mineral deposits, such as those with chalcocite and covellite, require flotation and smelting, while oxide ores are often processed using heap leaching.

Q2: How is copper extracted from ore?

A2: Copper is extracted from its source ores through crushing, grinding, flotation, heap leaching, solvent extraction, and electrowinning, depending on the ore type. In some processes, organic solvents are combined with other chemicals to separate and extract copper efficiently.

Q3: What is the largest copper mine in the world?

A3: The Escondida Mine in Chile is currently the largest copper-producing mine globally, with significant annual copper produced.

Q4: What environmental challenges are associated with copper mining?

A4: Challenges include waste management, acid mine drainage, habitat disruption, and the handling of sulfuric acid and TENORM. Environmental monitoring often compares background levels of radiological substances to those found at mining sites. Waste streams, such as raffinate, can contain concentrated amounts of TENORM, and these issues are closely monitored in the state of Arizona.

Q5: How does copper mining impact local communities?

A5: Copper mining provides employment, infrastructure development, and economic growth at the mine site, but requires responsible community engagement to address social and environmental concerns.