Mineral analysis in mining is a critical scientific process that unlocks the hidden value beneath the earth’s surface.

By accurately identifying and quantifying the minerals present in geological samples, mining professionals can make informed decisions that drive the success of exploration, extraction, and processing activities. Whether it’s determining the quality of ore, optimizing processing methods, or ensuring environmental safety, mineral analysis serves as the foundation for efficient and sustainable mining operations.

This article explores the essential techniques, applications, and significance of mineral analysis in the mining industry, providing valuable insights for students, professionals, and stakeholders interested in the future of mineral exploration and resource management.

Introduction to the Mining Industry

The mining industry is a cornerstone of the global economy, responsible for extracting valuable minerals and metals that are essential for modern life. At the heart of successful mining operations is mineral analysis, a process that allows mine operators to determine the elemental composition of geological samples and assess the quality of mineral deposits.

By using elemental analysis techniques such as X-Ray Fluorescence (XRF) analysis, mining professionals can quickly and accurately identify the concentration of valuable minerals within ore samples.

This information is critical for evaluating the economic viability of a mining project, as it helps determine whether the minerals present are of sufficient quality and value to justify extraction. Understanding the elemental composition of mineral deposits not only guides investment decisions but also ensures that mining activities are efficient and sustainable.

As the mining industry continues to evolve, the role of mineral analysis in identifying, quantifying, and valuing mineral resources remains more crucial than ever.

Why Mineral Analysis Matters

1. Ore Quality Assessment

Mineral analysis determines the ratio of valuable minerals to gangue (waste) minerals. Identifying differences in elemental composition between samples helps determine the variability and quality of the ore. For example, in a gold deposit, analysis will establish how much gold exists per ton of ore, which directly impacts whether extraction is financially viable.

2. Feasibility Studies

Before opening a mine, companies conduct feasibility studies, which heavily rely on mineral analysis. Analyzing the geological history of a deposit provides insights into its formation and potential extraction challenges. These studies inform decisions such as the size of the mine, the expected lifespan, and whether advanced technologies are required.

3. Process Optimization

Different ores require different beneficiation methods. Mineral analysis identifies the best processing method, whether flotation, magnetic separation, or leaching, reducing operational costs and improving recovery rates.

4. Environmental Management

Analysis also identifies harmful elements like arsenic, lead, or mercury. Understanding these contaminants in the mining environment is crucial for effective environmental monitoring and management. Knowing these in advance helps companies design safe waste management plans, avoiding issues such as acid mine drainage.

Mineral Exploration Techniques

Mineral exploration relies on a range of advanced techniques to locate and evaluate potential mineral deposits.

One of the most widely used methods is X-Ray Fluorescence (XRF) analysis, which enables rapid, non-destructive determination of the elemental composition of geological samples such as rocks, soils, and ores.

By exposing the sample material to X-rays, XRF analysis measures the unique spectral data emitted by each element, allowing for precise identification and quantification of valuable minerals.

In addition to XRF, electron microscopy is employed to obtain high-resolution images of mineral particles, providing detailed insights into the texture and structure of the sample.

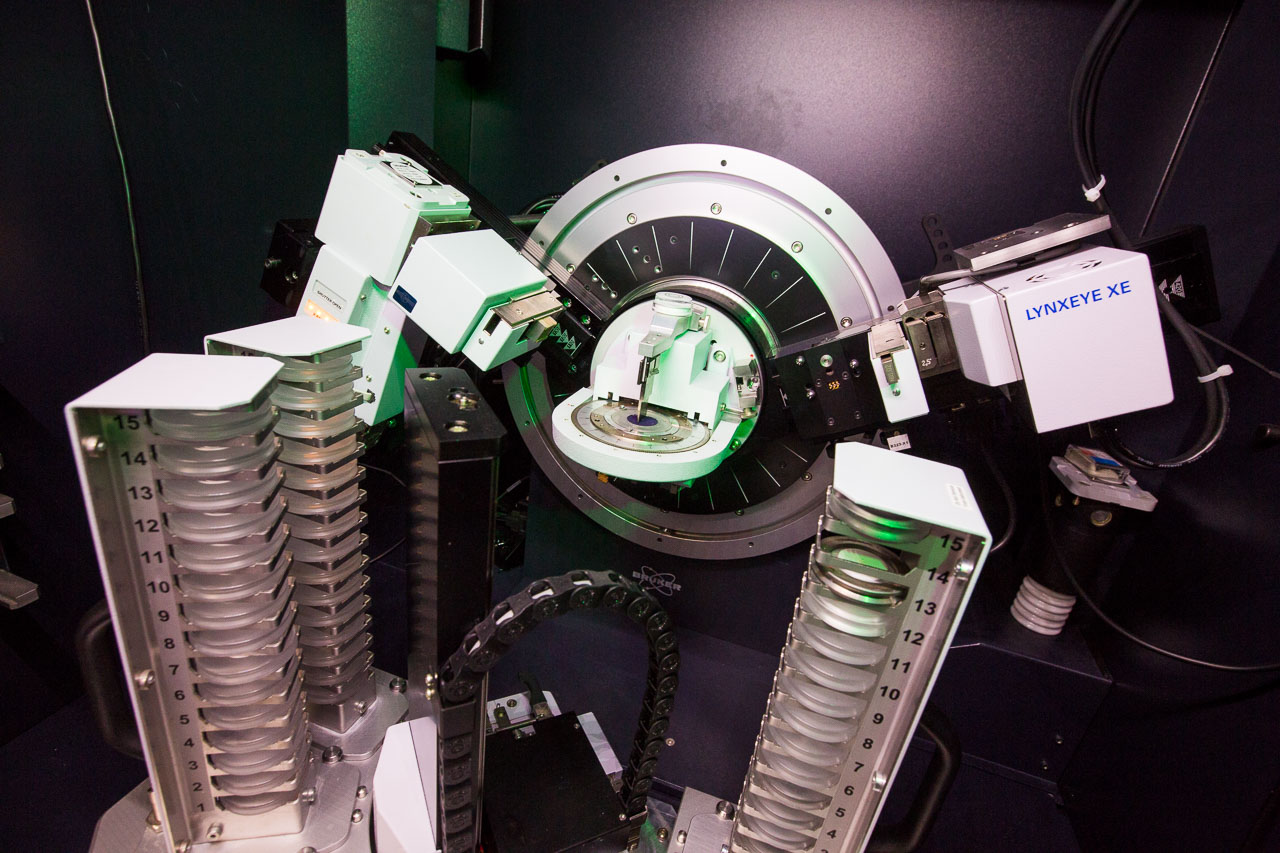

X-Ray Diffraction (XRD) is another key technique, offering information about the crystal structure of minerals, which is essential for distinguishing between different mineral species.

The combination of these methods allows for comprehensive quantitative analysis of geological samples, helping to determine the concentration and distribution of elements within a potential deposit.

Sample preparation, including grinding and sieving, ensures that the material is suitable for accurate analysis. The data collected from these techniques not only identifies the presence of valuable minerals but also supports the assessment of the economic viability of mining a particular site.

By leveraging advanced mineral exploration techniques, mining companies can make informed decisions about where to focus their efforts and how to maximize the value of their discoveries.

Methods of Mineral Analysis

X-ray Diffraction (XRD)

X-ray Diffraction (XRD) is a powerful analytical technique that reveals the crystal structure of minerals, which is crucial for differentiating between minerals with similar chemical compositions.

By directing X-rays at a powdered or finely ground sample, XRD produces a unique diffraction pattern or spectrum that allows researchers to separate and identify different mineral phases within a complex geological sample.

This technique not only identifies mineral species but also provides detailed information about crystallite size, lattice strain, and atomic substitutions within the mineral structure.

Additionally, XRD can be employed for spatial mapping of crystalline structures, offering valuable insights into the distribution and orientation of mineral phases across a sample.

This capability is essential for understanding ore genesis, mineral associations, and textural relationships that influence processing behavior and recovery rates.

X-ray Fluorescence (XRF)

X-ray Fluorescence (XRF) is a widely used, rapid, and non-destructive method that provides precise chemical composition data for geological samples.

By exposing the sample surface or powdered material to primary X-rays, XRF induces the emission of secondary (fluorescent) X-rays characteristic of the elements present.

This allows for the accurate determination of elemental concentrations, including key elements like potassium, iron, and trace metals, even at low levels.

XRF analysis is highly valued in both field exploration and laboratory settings due to its ability to handle a wide range of sample types with minimal preparation.

It supports quantitative analysis and quality control by identifying valuable minerals and detecting contaminants, thus informing decisions on mining feasibility and environmental management.

Atomic Absorption Spectroscopy (AAS)

Atomic Absorption Spectroscopy (AAS) is an essential technique for measuring trace amounts of metals such as gold, silver, and platinum in mineral samples.

This method involves atomizing the sample, typically after it has been ground and dissolved, and measuring the absorption of light at element-specific wavelengths.

AAS offers high sensitivity and specificity, making it suitable for detecting low concentrations of precious metals critical to economic evaluation.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) stands out as one of the most sensitive mineral analysis methods, capable of detecting elements at parts per billion (ppb) levels.

This technique ionizes the sample in a plasma torch and uses mass spectrometry to separate and quantify isotopes, enabling detailed elemental and isotopic analysis.

ICP-MS is especially important for assessing high-value deposits such as rare earth elements and for environmental monitoring of trace contaminants.

Gravimetric Analysis

Gravimetric analysis is a traditional yet reliable quantitative method where specific mineral compounds are chemically isolated, precipitated, and weighed to determine their concentrations in a sample.

Although more time-consuming than instrumental methods, gravimetric analysis provides a direct measure of mineral content and is often used to validate or calibrate other analytical techniques.

Sample Preparation and Combined Methods

Accurate mineral analysis depends heavily on proper sample preparation. Geological samples are typically crushed and ground into fine powders to ensure homogeneity and representative results.

Particle size control is critical, as variations can affect the accuracy and reproducibility of analytical measurements. Often, multiple methods are combined to provide a comprehensive understanding of mineralogy and elemental composition, leveraging the strengths of each technique to overcome individual limitations.

By integrating these diverse analytical methods, mining professionals gain a robust toolkit for characterizing mineral deposits, optimizing extraction and processing, and ensuring environmental compliance throughout mining operations.

Applications in Mining

- Exploration: Analysis helps identify drill targets by confirming mineralization zones.

- Mine Planning: Guides engineers in designing efficient extraction strategies.

- Processing Plants: Ensures that beneficiation processes are tailored for maximum yield.

- Rehabilitation: Post-mining analysis ensures that soils and water sources are free from harmful contaminants.

- Coal Mining: Rapid gas analysis, such as using micro gas chromatography (Micro GC), is essential for fast and precise measurement of methane, hydrocarbons, and sulfur compounds emitted from coal mines.

- Analytical Services: Comprehensive analytical services, including technical assistance, training, and maintenance, are available to support mining operations.

- Comprehensive Solutions: Integrated analytical solutions are designed to address challenges in mineral exploration and mining, ensuring effective, safe, and versatile operations.

Conclusion.

For beginners, it is useful to think of mineral analysis as the diagnostic test of the mining industry. Just like doctors rely on medical tests before prescribing treatment, mining companies depend on mineral analysis before investing millions in exploration and processing.

Mineral analysis ensures that mining operations are scientifically sound, economically feasible, and environmentally responsible. As technology evolves, the accuracy and speed of mineral analysis improve, making it indispensable in shaping the future of sustainable mining.

Frequently Asked Questions (FAQ)

What is mineral analysis in mining?

Mineral analysis in mining is the process of identifying and quantifying the minerals and elements present in geological samples. It helps determine the quality, composition, and economic viability of mineral deposits.

Why is mineral analysis important in the mining industry?

Mineral analysis is crucial for assessing ore quality, guiding feasibility studies, optimizing processing methods, and managing environmental risks. It ensures mining operations are efficient, profitable, and environmentally responsible.

What are the common techniques used for mineral analysis?

Standard techniques include X-Ray Fluorescence (XRF), X-Ray Diffraction (XRD), Atomic Absorption Spectroscopy (AAS), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), and gravimetric analysis. Each method provides unique insights into mineral composition and structure.

How does sample preparation affect mineral analysis?

Proper sample preparation, including crushing and grinding to a consistent particle size, is essential to obtain representative and accurate results. Poor preparation can lead to contamination or inconsistent data.

Can mineral analysis help in environmental management?

Yes. Mineral analysis can detect harmful elements such as arsenic, lead, or mercury in mining environments, aiding in monitoring and mitigating environmental impacts.

What role does mineral analysis play in mineral exploration?

It helps identify zones of mineralization, assess the concentration of valuable minerals, and supports decision-making on where to focus exploration efforts.

Are there on-site mineral analysis techniques?

Yes. Portable XRF analyzers allow for rapid, non-destructive elemental analysis directly at mining sites, enabling quick decision-making without the need to transport samples to laboratories.

How does mineral analysis contribute to mine planning and processing?

By providing detailed information about the mineral composition and distribution, mineral analysis guides the design of extraction strategies and processing methods to maximize recovery and reduce costs.